| EnviroVAr Power Factor Control System

The EnviroVAr power factor correction provides effective reactive

power compensation for all industrial, commercial and large retail

environments where excess charges are being applied and or where

current availability is limited and the cost of a replacement transformer

or increased supply is prohibitive.

The Problem

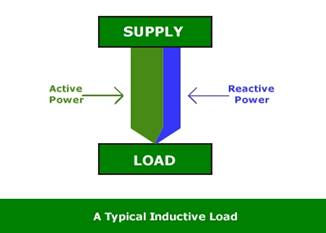

Most three phase electrical loads draw not only active power

(kW, the part that does useful work), from the supply, but also

reactive power (kVAr, essential, but ‘Wattless’ power); examples

of these loads would be induction motors, motor drives (both AC

and DC ) , switch-mode power supplies, and most forms of lighting.

|

|

|

To make a very crude example of an induction motor,

the active power is what comes out of the shaft and does work,

whilst the reactive power is what is used by the coils of the stator

to create the magnetic field. This magnetic field is essential

for the operation of the motor, but does no actual work, only permitting

the transfer of power from the stator to the rotor.

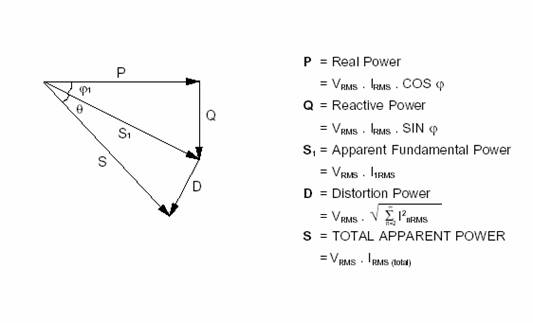

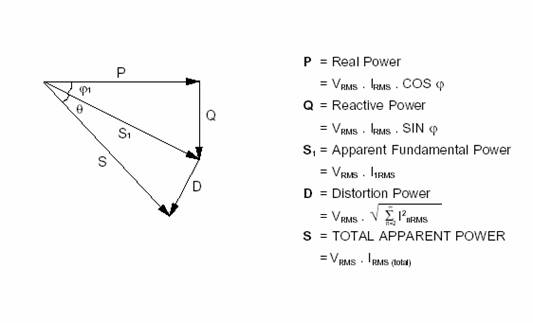

The total demand on the supply for a load of this type is called

the apparent power, and is the vector sum of both the active and

reactive components of power. The ‘power factor’ of a load is the

ratio of active power to apparent power, kW to kVA, sometimes referred

to as Cos ( f ). When a load draws reactive power from the supply,

its power factor is said to be lagging, when the reactive power

is exported to the supply, its power factor is said to be leading.

This is a reference to the phase of the load current with respect

to the supply voltage.

This is the ‘Displacement Power Factor’ or DPF, more commonly

known as just the ‘Power Factor’ and only takes into consideration

the frequency components of voltage and current.

|

|

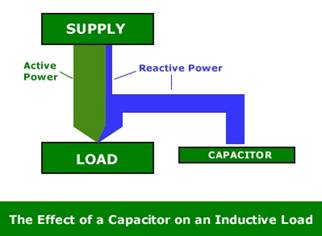

When seeking to improve the power factor of a load, what is actually

being done is to supply a proportion of the reactive power demand

of this load locally. This results in a greater proportion of active

current being drawn from the supply.

|

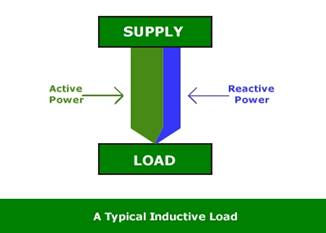

With no power factor correction equipment installed, the supply

is required to provide the total active and reactive power demand

of the load.

|

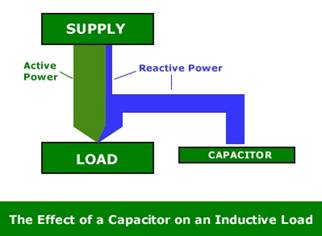

With a capacitor installed electrically adjacent

to a load, the supply is required only to provide the active power

demand, and a smaller proportion of the reactive power demand.

|

Physical Benefits of Power Factor Correction

The reduction in demand on the supply from the installation of

Power Factor Correction equipment results in:

- ‘Spare’ supply capacity which may be used to connect additional

load without the necessity of network reinforcement

- Reduced losses and hence reduced heating in transformers,

cables and switchgear, increasing reliability, useful service

life, and reducing servicing costs

- Reduction in reactive power demand from the supply improves

voltage regulation, as to a first approximation, the voltage

drop in a supply network is proportional to the reactive power

supplied by that network ( D V @ QX, where D V is the voltage

drop, Q the reactive power demand, and X the system reactance)

- An increase in Power Quality, as the presence of a large capacitor

bank gives significant attenuation of mains borne voltage spikes,

and can also reduce the effects of short duration dips or notches

in the supply voltage

- Reduction in distribution system losses means that fewer kWh

are required from the electricity generators, resulting in lower

carbon dioxide emissions

Contractual benefits of Power Factor Correction

- Most contracts for the supply of electricity stipulate a minimum

power factor for the load to be connected, though this is often

ignored by both supplier and consumer until problems occur, at

which point the solution is more costly than would have been

the case had the situation been addressed initially

- Engineering Recommendation G5/4, (relates to planning levels

for harmonic voltage distortion and the connection of non-linear

equipment to transmission systems and distribution networks in

the United Kingdom), is now enforceable legislation. The use

of detuned capacitor banks has the effect of absorbing a proportion

of any harmonic currents produced by the load, and can often

result in compliance with G5/4 without the need for further harmonic

reduction equipment.

- Engineering Recommendation P28, (relates to planning limits

for voltage fluctuations caused by industrial, commercial and

domestic equipment in the United Kingdom), details limits on

‘Voltage Flicker’. As the majority of flicker is caused by voltage

drop due to sudden reactive power demand, the installation of

power factor correction capacitors can reduce the levels of flicker

to within acceptable limits without the need for supply reinforcement.

- Organizations having or seeking approval under ISO14001 (Environmental

Management) can easily show increased electrical efficiencies

and reduction in carbon emissions by implementing an appropriate

Power Factor Correction scheme.

Financial Benefits of Power Factor Correction

- Reduction in kVA required to supply a given kW load means

that initial capital expenditure can be reduced, as the primary

distribution network components (transformers, switchgear etc.)

can be reduced in rating and hence Cost.

- Reduction in losses in distribution equipment due to reduced

demand on the supply is reflected in the kWh usage for the site.

Whilst this reduction in kWh consumption may at first appear

to be small, it can amount to between 1% and 3% of the total

consumption, with the associated savings in electricity charges.

- The tariff under which charges are made for electricity may

include items which relate directly or indirectly to poor power

factor. These are usually specific to the consumer, and hence

generalizations are difficult. Items falling into this category

which may be affected include Authorized Supply Capacity, Metered

Monthly Maximum Demand, and Reactive Unit charges.

EnviroVAr systems are available as both "standard" systems and

also as "detuned" systems with additional inductive reactive filters

to limit harmonic currents within a circuit. For a full understanding

of these systems go to the links above and then contact your local

EMS (European) representative to arrange a site survey to best

advise you as to how you can benefit from effective power factor

correction

|

|

|